The Tobacco Industry in Wheeling, 1931

- from Forward Wheeling (a publication of the Wheeling Chamber of Commerce), [vol. 1], no. 2, February 1931. p. 8-9, 13.

Wheeling: Tobacco Center

By Peter Boyd

IT HAS been estimated that the Wheeling district has within its bounds more than two hundred and fifty industries encompassing almost the whole gamut of industrial enterprises.Of these there is probably none which has greater renown than the tobacco industry. Its history dates back to the day when the city of Wheeling was beginning its industrial growth and its present volume of manufactured products compares favorably with many apparently larger industries.

There are two kinds of tobacco products made in the Wheeling district; stogie and ribbon cut tobacco used for chewing and smoking. Both are important products of the district the manufacture of which employs large numbers of people.

Without wishing to choose between the importance of the two industries which, although classified as tobacco manufacturing enterprises, are widely varied in methods, we will first discuss the stogie industry.

The first stogie, as far as is known, was rolled just thirty miles from Wheeling, in Washington, Pa., in the year 1818. George W. Black, Sr., was the inventor who took in his two hands a few tobacco leaves and rolled them into a long thin cigar. In the same year the National Road was completed to Wheeling from Cumberland, Md., giving the seaboard and the Ohio Valley the first direct transmontane travel connection. Over this road freight was hauled by means of Conestoga wagons, an equipage much like the covered wagon we now see in the movies. Imbued, no doubt with the romance of the overland trail Mr. Black called his product Conestogas, the name which has been shortened throughout the years to stogies, a natural contraction.

It is said that the stogies of local manufacture made many friends at the very outset and according to records of an early manufacturer many celebrities of the country's early history bought them for their own use. Among these users were; Presidents, James Monroe, John Quincy Adams, Abraham Lincoln, Prince Louis Phillippe, later King of France, Henry Clay, Daniel Webster, the Marquis de Lafayette, James G. Blame, P. T. Barnum, General Sam Houston, General Santa Anna of Mexico, Black Hawk the Indian Chief and others.

In the early days of the development of Wheeling stogies, they were distributed in either one of two ways. The wagon drivers on the National Road would take them east with them as a sort of back load for their wagons. This formed for the early stogie makers a most profitable market along the eastern seaboard in the vicinity of Baltimore and Washington.

The other outlet was, quite naturally, the river trade. The shipyards formerly located in Wheeling, were a training school for men looking forward to a life of trade on the internal waterways of the United States. It is quite likely that these men cultivated a taste for Wheeling stogies while working here and continued to smoke them after they had left Wheeling for their life of roaming.

The older men in the industry remember when tow-boats, coming down the river, would put off a row-boat manned by several strong oarsmen to get supplies at Wheeling. These boats would leave the big boat when opposite the site of old Top Mill and row ahead to the Wheeling wharf. Then the men would run up to get supplies, catching the boat as it passed the point where Wheeling Creek meets the Ohio. These supplies, according to the old stogie-rollers, always contained a liberal number of Wheeling stogies.The manufacture of stogies began in Wheeling in 1840, almost a century ago, when Mifflin M. Marsh opened a little shop on Fourteenth between Main and Water Streets and there rolled with his own hands the first stogie turned out in Wheeling.

M. Marsh and Sons Inc.

From this humble beginning has arisen the present firm of M. Marsh & Sons Inc., the oldest and one of the largest stogie manufacturing companies in the world.

Seven years after the first stogie was rolled by Mifflin Marsh, he took his son William Marsh into the business. The first factory was a crude affair, consisting only of one small room having in it several hand hewn benches on which the stogies were rolled. Barrels were placed behind these benches and as soon as a stogie was completed the roller pushed it back so it would fall into the barrel. Upon being taken from the barrels the stogies were gathered in groups of twelve and bundled for sale in that form.

The waggoners, according to the pioneers, would often take a considerable number of stogies back to the Atlantic Seaboard, where after a little while there rose a considerable demand for them.Thus it is seen that the reputation of M. Marsh & Sons and the fame of the Wheeling Stogie grew hand in hand.

It was not long until the first quarters of this growing company proved too small so the company moved to a building on Water Street just below Twelfth. It was in this building that the now famous M. Marsh & Sons, "Pioneer" stogie was developed.

From Water Street the factory was moved to a building on Twelfth Street between Water and Main Streets, where the Miller Transfer Company is now located. And from there the factory was moved to Market Street where it is now located.

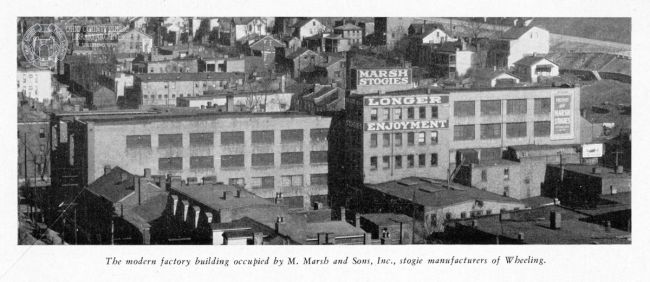

The present factory, at 911-913 Market Street was formerly a three story structure, but shortly after the Marsh Company moved into it another story was added. Later the building next door was aquired by the company and in recent years a five story building was erected in the rear of this extending through to Main Street.

The present factory, at 911-913 Market Street was formerly a three story structure, but shortly after the Marsh Company moved into it another story was added. Later the building next door was aquired by the company and in recent years a five story building was erected in the rear of this extending through to Main Street.

Mifflin M. Marsh, the founder of the business died in 1901. His son William was in active charge of the business until his death in 1921 and since that time the company has been under the management of John J. Wolfe, one of the leading stogie experts of the world.

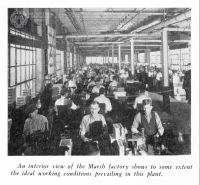

Methods of stogie manufacture have changed very little during the years since Mifflin Marsh rolled the first cheroot. They are still made by hand on benches by "stogie rollers." Conditions under which the rollers work, however, have changed greatly, for where once the workmen labored in small stuffy rooms, today they roll the stogies in light, airy factory building, under ideal conditions.

Methods of stogie manufacture have changed very little during the years since Mifflin Marsh rolled the first cheroot. They are still made by hand on benches by "stogie rollers." Conditions under which the rollers work, however, have changed greatly, for where once the workmen labored in small stuffy rooms, today they roll the stogies in light, airy factory building, under ideal conditions.

In 1871 another stogie company was formed which was destined to become one of the city's leading industries. This was called the Pollack Stogie Corporation and was founded by Augustus Pollack.

The Pollack Stogie Corporation

The first factory operated by this organization was on Main Street south of Twelfth. Later Mr. Pollack moved his factory to Water Street just south of Twelfth Street, where a large factory is still operated. As Pollack's stogies became more popular, however, it proved that this factory was not large enough to supply the demand. Augustus Pollack then built the factory, at that time the largest in the world, which covers a whole city block bounded by Eoff, Chapline, Eighteenth and Nineteenth Streets in Wheeling. Augustus Pollack was truly a great business man. His stogie industry flourished with the years as he proved himself a brilliant merchandiser and factory manager.

The first factory operated by this organization was on Main Street south of Twelfth. Later Mr. Pollack moved his factory to Water Street just south of Twelfth Street, where a large factory is still operated. As Pollack's stogies became more popular, however, it proved that this factory was not large enough to supply the demand. Augustus Pollack then built the factory, at that time the largest in the world, which covers a whole city block bounded by Eoff, Chapline, Eighteenth and Nineteenth Streets in Wheeling. Augustus Pollack was truly a great business man. His stogie industry flourished with the years as he proved himself a brilliant merchandiser and factory manager.

Mr. Pollack was beloved of those who worked for him to an extent seldom seen. His employees had at all times access to his private office, where they were urged to come once in a while to talk over conditions under which they worked, wages and such things. At this time this practice, since become quite common, was an innovation in factory management. Mr. Pollack proved its worth in dividends of satisfied workers and often boasted that during his long and active life he had never had one bit of labor trouble in his large factories.

After his death, Augustus Pollack's employees erected a monument to his memory, probably the first and only shaft ever raised to an employer by the men who worked for him. This large monument, with statues of an employer and an employee shaking hands in amicable agreement may be seen today on the Northwest corner of the grounds of the City-County Building in Wheeling. It was erected with money raised by subscription among the members of the Ohio Valley Trade and Labor Assembly, a fitting tribute to a pioneer paid by those who worked for him.

Pollack "Crown" Stogies are as well known as any manufactured in the Wheeling district and have done their part to make Wheeling famous for its hand made cigars.

The J. F. Miller Company

Another Company deserving of special mention is the J. F. Miller Company, manufacturers of the famous "J. F." stogies. The company has been engaged in the manufacture of stogies for many years and recently has started an expansion program which includes better manufacturing facilities and modern merchandising endeavors. This company is not as old as the two mentioned previously but its progress has been considerable. The quality of JF's has never been questioned, they are rolled by master craftsmen of the best tobacco available. As they are becoming known the production has been increased until today the J. F. Miller Company occupies a prominent place in the list of our city's industries.

Another Company deserving of special mention is the J. F. Miller Company, manufacturers of the famous "J. F." stogies. The company has been engaged in the manufacture of stogies for many years and recently has started an expansion program which includes better manufacturing facilities and modern merchandising endeavors. This company is not as old as the two mentioned previously but its progress has been considerable. The quality of JF's has never been questioned, they are rolled by master craftsmen of the best tobacco available. As they are becoming known the production has been increased until today the J. F. Miller Company occupies a prominent place in the list of our city's industries.

There are numerous smaller stogie factories in the Wheeling district which employ a large number of people. It is difficult to outline the history of all of these concerns. It is even difficult to estimate the number of them in existence. The Wheeling stogie is, by its very nature, a hand made product. Its manufacture is such that large operations, while they effect certain economies cannot hope to monopolize the business. Anyone who knows the stogie-rolling business can set up a factory in the garret or basement of his house and before long become a manufacturer in his own right. As a result of this condition there are actually hundreds of little "one-man" stogie factories in and about the Wheeling district. The stogie industry is a large one yet one which is scattered far and wide within the Wheeling area. An index of its size may be obtained from the fact that during the year just past nearly $160,000.00 was collected by the Government forrevenue stamps to be used on stogies. The business of manufacturing the boxes required for this enormous supply of stogies, also adds considerable to the army of workers and the payrolls of Wheeling.

Bloch Brothers, Manufacturers of Mail Pouch

In 1879 S. S. Bloch went into the wholesale grocery business in Wheeling, and at the same time started a little factory next door to make cigars. From this humble beginning has risen one of the city's largest and best known industries, the Bloch Brothers Tobacco Company, manufacturers of Mail Pouch tobacco.

In 1884 the grocery stock of the company was destroyed by flood and from that time on the company gave over its entire resources to the manufacture of tobacco products.

In 1891, when the company was incorporated it had a capital stock of $2,000,000. The authorized stock today is $10,000,000. Cigar manufacture long ago was discontinued by the company and today they make only one product, the far famed Mail Pouch, the original ribbon cut chewing and smoking tobacco.

Aaron and Samuel Bloch formed the original partnership of the company. When the company was incorporated in 1891 Aaron Bloch was named the first president. He was succeeded by Samuel Bloch who has since held that position.

The executives of the company have always been men of business ability and acumen. Jesse A. Bloch, a son of S. S. Bloch, is Vice President of the company and has assumed active management of the enterprise. He is a man who has distinguished himself in public as well as private affairs. From 1912 to 1916 he was a member of the House of Delegates of West Virginia and from 1919 to 1921 he represented his district in the Senate of West Virginia.

Other executives of the Bloch Brothers Company are: Harold S. Bloch, second vice-president; W. M. Tiernan, third vice-president; Robert Lee Boyd, secretary; W. J. Frankston, vice-president and manager of sales promotion; S. R. Morrow, manager of production; Thomas M. Bloch, manager of leaf department; H. L. Robinson, superintendent; G. C. H. Friedrich, master mechanic.

The company today occupies a group of buildings having in excess of 400,000 square feet of floor space, or approximately ten acres. The annual production of Mail Pouch is over 120,000,000 packages a year.The steady growth in the demand for this famous Wheeling product is due greatly to the quality of the ingredients and the care used its treatment, preparation, and packing.

Wisconsin, Pennsylvania, Connecticut and Ohio contribute their best leaf to Mail Pouch. The process for blending the different kinds of tobacco has never been changed.

Wisconsin, Pennsylvania, Connecticut and Ohio contribute their best leaf to Mail Pouch. The process for blending the different kinds of tobacco has never been changed.

After the blending process, the tobacco is put into containers to remain over night, so that the flavor may penetrate the leaves. It is then conveyed to the cutting machines, where it is pressed into a block and fed into cutters.Extremely sharp knives revolving at great speed cut the leaves into strips or ribbons. Hence the name "ribbon cut." To call this tobacco scrap tobacco is erroneous. That implies that the tobacco is prepared from leavings. This is not true as only the highest grade of leaf tobacco goes into the making of Mail Pouch.

From the cutter the tobacco is taken to the drying department. Here it passes through large cylindrical, steam drying machines, where the moisture in the tobacco is driven off by vaporization.The treated tobacco is then stored in metal carriages until it is packed. In the packing operation the tobacco passes into magazines which feed the automatic packing machines. Paper bags are placed in another part of the machine. An automatic device grips the bag, opens it, places it over a funnel through with the tobacco flows from automatic box scales. The top of the package is then folded, sealed stamped, and reweighed.

The filled packages are then sent to the floor below by continuously moving conveyors and elevators. Here machines wrap them in wax paper and seal them. After being packed rapidly in large cartons, Mail Pouch is ready to be sent to more than 500,000 dealers in various parts of the world.Mail Pouch Tobacco is one of the most widely known products made in the Wheeling district. It is used alike by oil drillers, structural workers, laborers, ministers and legislators. Its merit has won it fame far from the bounds of the city of its home, and successful merchandising has extended its markets to almost every corner of the globe.

And so we see that Wheeling is truly a Tobacco City. Its stogies and its Mail Pouch are among the best known and most widely demanded products among tobacconists throughout the world. We can well be proud of the industry and the men who have made it what it is today. It is one of Wheeling's greatest industrial enterprises employing hundreds of skilled workmen who are a part of the citizenry of our district. Men and women who have a real live interest in the community in which they have lived for years, connected with an industry almost as old as the city which has it for its own. It is such industries and such workers that make a city just a little better than it could possibly be without them.

Tobacco Industry | Wheeling Businesses | Places of Wheeling Home | Wheeling History Home | OCPL Home

Want to keep up with all the latest Library news and events?

Want to keep up with all the latest Library news and events?